We are the official technology partner bringing Alcemy’s AI platform to Indian cement manufacturers, helping them transition to sustainable, efficient, and climate-friendly production.

AI-Driven Quality Control and Optimization for Cement Plants

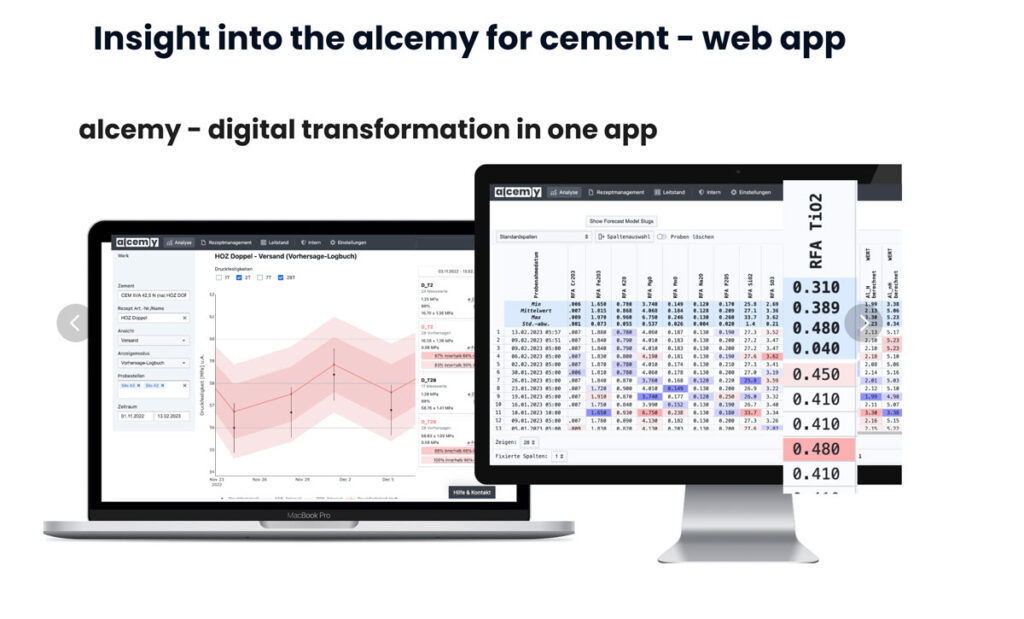

Alcemy for Cement

alcemy tackles a pressing challenge in the cement industry: to achieve meaningful decarbonization, the share of clinker must be drastically reduced. This shift, while critical for sustainability, introduces new complexities—such as difficulty meeting strength targets and increased labor demands.

alcemy is transforming this challenge into an opportunity. Our AI-powered predictive quality control software makes decarbonization both technically feasible and economically advantageous. By simply exporting lab data from XRF, XRD, and Laser PSD devices, our machine learning models accurately predict compressive strength in real time and recommend precise target fineness adjustments—enabling producers to consistently hit quality targets during production.

All of these insights are available through our personalized, cloud-based WebApp, which delivers real-time performance analytics tailored to each client’s production environment.

By seamlessly integrating AI into quality control, alcemy empowers cement producers to:

- Maintain consistently high product standards

- Reduce material and energy costs

- Boost operational efficiency

- Confidently accelerate their path toward low-carbon cement

As of 2025, alcemy is operational in over 30 cement plants across 12 countries, optimizing the production of more than 33 million tons of cement annually. Our technology is not just a software solution—it’s a strategic asset for the future of cement manufacturing.

The question isn’t if AI will redefine cement production—it’s when you’ll start benefiting from it.