Bricking Machines

Precision and Safety for Faster Kiln Maintenance

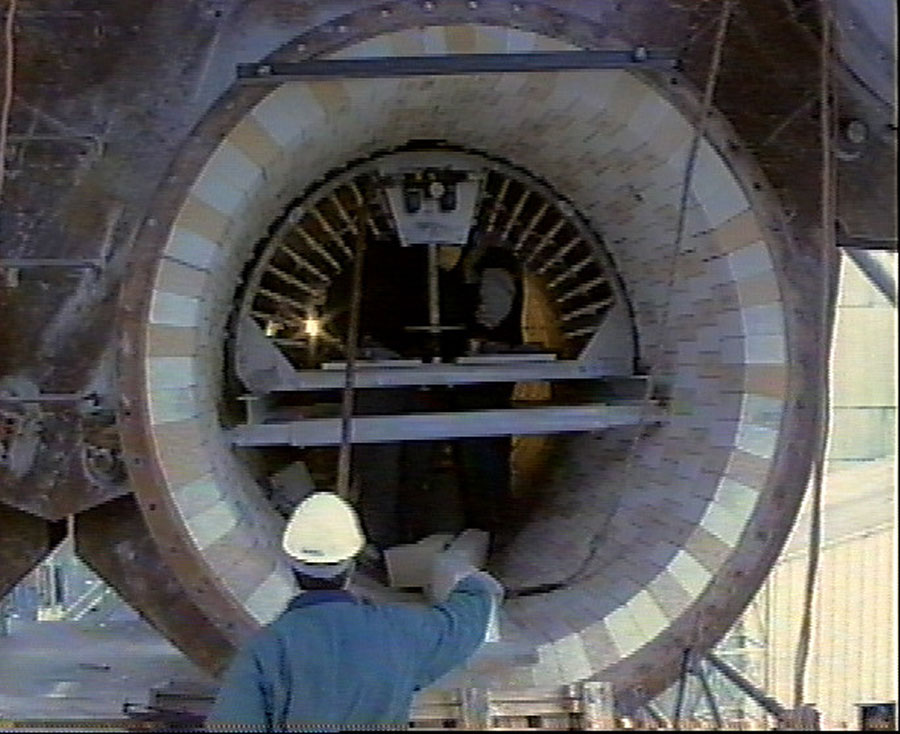

About Bricking Machines

Innovative Solutions for Efficient, Safe, and Streamlined Refractory Installation

Bricking Solutions Inc. specializes in innovative bricking machines designed to streamline the process of installing refractory linings in rotary kilns and other large industrial vessels. These bricking machines are engineered to enhance safety, efficiency, and precision, allowing for faster and more accurate brick installation. With features such as adjustable arches, ergonomic designs, and user-friendly controls, Bricking Solutions’ machines cater to a variety of kiln sizes and configurations, minimizing downtime and labor costs while ensuring high-quality installation. Their solutions are widely used in industries such as cement, lime, steel, and aluminum production.

EZ Flexx50 Small Bricking Machine

The EZ Flexx50 Small Bricking Machine offers the same advanced safety and efficiency features as the larger models but in a more compact size, specifically designed for kilns ranging from 3 to 4 meters (9’ 10” – 13’ 1”) in diameter, with a brick ID of 2640 mm to 3640 mm. This smaller machine boasts a 3,000 kg load capacity and adheres to stringent safety standards, including CE, MSHA, CSA, and AWS. It is an ideal solution for industries needing efficient and safe brick installation in smaller kilns without compromising on performance or reliability.

EZ Flexx50 Bricking Machine

The EZ Flexx50 Bricking Machine is engineered with a flexible arch, allowing for easy adjustments to accommodate minor kiln distortions, conical sections, or ovality. This versatile machine is available for any kiln size within a 2-meter range from 4 meters and up, or it can be custom-designed to meet specific plant requirements. Featuring a standard load capacity of 4,000 kg (8,800 lb) and a 4.3-meter (14’) work platform, the EZ Flexx50 can support two pallets of bricks (1,540 kg) plus workers and equipment, offering the highest load capacity in the industry. With a variety of additional efficiency-enhancing features, it stands out as the safest and most effective bricking machine available, significantly speeding up refractory brick kiln installations.

Mini Econ-O-Ring Bricking Machine

The Mini Econ-O-Ring (MECOR) Bricking Machine is an adjustable, cost-effective solution for small-duty applications, designed to service kilns with a brick ID ranging from 1295mm to 2489mm (51″ to 98″). This single-arch bricking machine features a single adjustable frame system, enabling it to accommodate various diameter combinations within its specified range. Ideal for burning chambers in paper mill drying kilns, tertiary return ducts in cement plants, satellite cooler tubes, small vessels, kilns, and furnaces, the MECOR is constructed from lightweight aluminum and can be assembled in just 30 minutes. Its compact components can be easily handled by two people, making it a versatile and efficient choice for smaller-scale refractory installations.

Econ-O-Ring Bricking Machine

The Econ-O-Ring (ECOR) Bricking Machine is a versatile, economically priced, medium-duty machine designed for brick lining in kilns with a brick ID of 2489mm to 3658mm (98″ to 144″). This double-arched machine features a unique adjustable frame system and multiple hinged arch sections, allowing it to accommodate various diameter combinations within its range. Specifically designed for smaller kiln diameters, the ECOR is made from lightweight aluminum and can be assembled in just 60 minutes once inside the kiln. Its small, manageable components can be easily handled by two people, making it ideal for kilns with limited access. The ECOR is capable of installing both insulated and active bricks in lime kilns, enhancing its functionality and efficiency in medium-duty applications.

Torpedo Ladle Brick Lining Machine

The Torpedo Ladle Brick Lining Machine by Bricking Solutions Inc. is specifically engineered for efficiently installing refractory linings in torpedo ladles used in the steel industry. It eliminates the need for traditional wooden forms and wedges, significantly reducing setup and installation times. Crafted from durable 6061-T6 aircraft aluminum, the machine features custom Aluminum Perf-O-Grip Planking and a sturdy aluminum frame with a net capacity of 2,722 kg (6,000 lbs), supported by rails for the trolley. It incorporates a custom-made flex arch with flexible hinge connections, allowing the arch wings to adjust toward and away from the kiln wall as needed. Additionally, an arch stabilizer post ensures precise positioning of the arch relative to the ladle shell, enhancing stability and accuracy during the lining process.

Stair-Stepped Bricking Machine

The Stair-Stepped Bricking Machine by Bricking Solutions Inc. incorporates the advanced features of the EZ Flexx50 but with a unique stair-stepped design that provides substantial clearance under the bricking rig. This clearance allows support equipment such as skid steers or forklifts to drive under the machine, facilitating easier deposition of refractory brick on the keying side. Available in models designed for 4- to 5-meter and 5- to 6-meter kilns, it offers clearance heights of approximately 213 centimetres (84 inches) and 264 centimetres (104 inches), respectively, depending on the machine configuration and kiln size. Known for having the industry’s largest capacity and ample deck space for bricks, personnel, and tools, the Stair-Stepped Bricking Machine enhances efficiency and safety during refractory brick installation.